Due to the frequent drought periods that have been affecting the coastal area of Santa Cruz in Guanacaste, a company finances the creation of a desalination plant which will produce 23 liters of drinking water per second, specifically in the Conchal Reserve, Guanacaste. The project is in charge of the company Florida Ice & Farm (Fifco) after seeing the consequences caused by the strong droughts that have occurred in the area.

“This type of innovative works are of great importance for the country, especially as it is a project that is located in an area that has been very affected by the drought”, said Gisela Sánchez, Director of Corporate Relations. The desalination process is carried out through reverse osmosis. With the application of electrical energy, a high pressure is generated in the seawater in specialized equipment in the semipermeable membranes that let the water molecules pass but not the salt molecules.

The marine biology studies carried out indicate that there are no sensitive marine ecosystems that can be affected by the seabed at the seawater intake point, as well as in the brine discharge (water with a high concentration of dissolved salt) desalination process.

“The impacts are minimal and are related to the proper disposal of the brine and the consumption of electric power”, says Sánchez. The start of the design and construction process began in 2014, which involved the installation of underground piping for the collection and discharge of the brine.

However, the main thing is to install the 4 modules that were envisaged from the first phase of its construction, since the plant will have the capacity to generate 23 liters per second of drinkable water.

How does the desalination plant work?

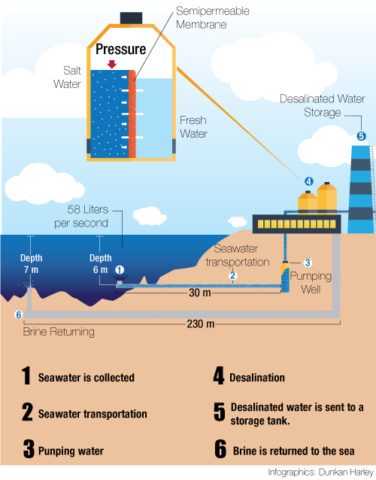

The 1st step of the process is the capture of marine water. This is done 230 meters away from the beach and must have a depth of 6 meters below sea level.

Once the collection of material has been completed, the transfer of seawater should be continued. It will be conducted through a polyethylene pipe, high density, which will be located under the seabed to a pumping station 215 meters into the beach.

Then the seawater is pumped to a location where the desalination plant is located, 480 meters from the pumping well. All this process will be done through a pressure pipe of 150 millimeters in diameter. Then the process of desalinating the water begins with reverse osmosis technology.

This works by applying electrical power to specialized equipment that produces a high pressure in the seawater against semipermeable membranes. The H2O molecules are forced to pass through the micro-pores of the membranes.

However, these do not allow the passage of salt molecules, making it suitable for use and consumption. After carrying out the “water cleaning” process, it is stored and used. When it is ready the material is stored in a tank for its further use.

To finish, according to Diego Gutiérrez Fonseca’s approach, an associate of the American Water Works Association and expert of the Instituto Costarricense de Acueductos y Alcantarillados, the desalination plant represents a new step to consolidate Costa Rica’s regional leadership with regard to the “green” policies towards an environmentally-friendly use of water for human consumption.