Since its inception, 3D printers have been a great help to medicine creating from functional prostheses to custom bones, but scientists want to go for more. The new challenge of 3D printers is to create human organs that can be printed on special machines and, through which it would end not only with the large waiting lists for transplants but also with most cases of rejection.

Bioprinting is the future of medicine

For years, attempts have been made to grow human tissues in laboratories, especially using stem cells, but in the case of organs, the results have not been successful. Bio-printing promises to mix laboratory work with very special printers, capable of taking cells grown in the laboratory and, through a special process, transforming them into a type of organs tailored to the patient.

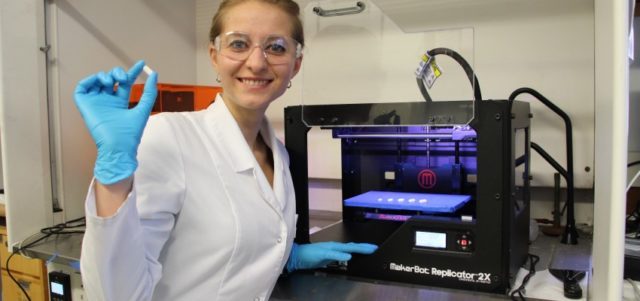

The impression of human organs has several stages. First, scientists take samples of the patient’s tissues or stem cells, which are grown in the laboratory, waiting for them to multiply.

Subsequently, these cells are transformed into a kind of biological ink, which is what is used in bioprinting. The printers are programmed to create different organs, all tailored to what the patient requires.

A model of these cells, already differentiated for use, is printed in 3D, and then implanted in the human body, waiting for them to merge with existing cells, replacing the organ that fails. An organ is not printed as we know it, but rather cellular assemblies that are capable of performing the processes that are not functioning as they should due to the failure of the organ in charge.

Benefits and advantages of bioprinting

Bioprinting, which will be really costly at first, is a great benefit in the area of transplants: it will not be necessary to expect an organ from an available body to finish the long lists. In the United States only, 18 people die each day expecting an organ transplant.

In addition, the surgical intervention that transplants involve today is very risky and, when using tissues, the complexity of the operation decreases significantly. Finally, the rejection of transplanted organs, a major problem for patients who must consume immune-suppressants for life, goes down a lot, since cells from the same person are used.

A great advance in 3D Printing: replicating parts of collagen heart is announced

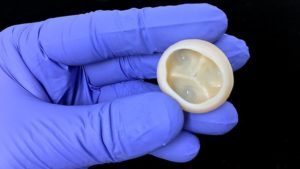

American scientists successfully created parts of a collagen heart by using a 3D bio-printer, a technological breakthrough thanks to which they could, someday, create entire organs. Their technique, which was published in the “Science” journal last week, replicates the complex biological structures of the body that provide the configuration and biochemical signals necessary for the organs to function.

“We can show that it is feasible to print a collagen heart valve in 3D and that it works”, said Adam Feinberg, one of the study’s co-authors. Previous attempts to create these structures, known as extracellular matrices, failed because the prints had a low resolution or the tissue was invalid.

Collagen is a perfect biomaterial for these projects since it is found in all tissues of the human body. It is fluid, so initially, when trying to print it, became a gelatinous material.

But the scientists at the Carnegie Mellon University (CMU) were able to deal with the problem by using rapid PH changes so that the collagen solidified in a controlled and rapid manner. “This is the first version of a valve, so everything we get will be better and better”, he added.

The technique could one day help patients waiting for a heart transplant, but it must first be validated with tests on animals and eventually on men. “I think that, in the short term, it will serve to repair an existing organ such as a heart with the loss of functioning due to a heart attack or a degraded liver”, Feinberg concluded.